Univ.-Prof. Dr.-Ing. Mark W. Hlawitschka (JKU Linz)

Univ.Prof. Dr.-Ing. Alfredo Soldati (TU Wien)

Project Description

Background and State of the Art

Water is the foundation of life, economic growth and ecosystem health. Yet rapid urbanisation, industrialisation and intensive agriculture are straining freshwater supplies. With climate change intensifying droughts and pollution, the safe treatment and reuse of wastewater has become a cornerstone of environmental stewardship. Beyond a technical obligation, it is now a social imperative central to the UN Sustainable Development Goals (SDGs).

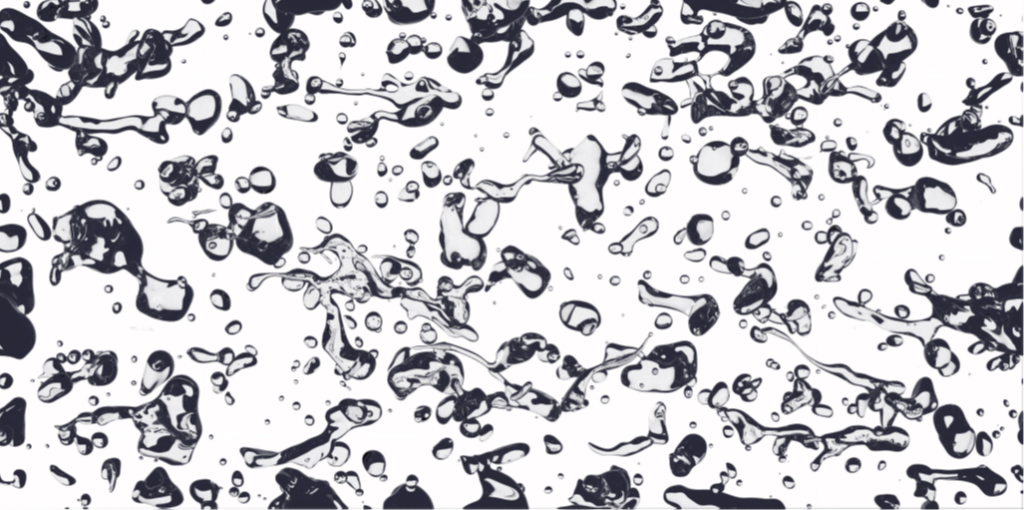

Conventional wastewater treatment processes – sedimentation, biological degradation, filtration – remain indispensable. But they increasingly struggle with “modern” pollutants such as microparticles, microplastics, oil–water emulsions and emerging industrial contaminants. To meet these challenges, flotation techniques have re-emerged as a key technology. Dissolved and induced air flotation (DAF/IAF) efficiently separate fine suspended solids, oils and hydrophobic substances that are hard to remove by other means, while offering compact footprints and rapid processing times. Tiny bubbles capture thereby the impurities and transport them to the surface where they can be collected and removed (Fig. 1).

Municipal water reclamation, food processing, mining and textile industries now rely on flotation to meet stringent discharge standards and enable resource recovery.

Flotation also supports broader societal goals: reducing pollution loads to natural waters, recovering valuable materials from waste streams, enabling decentralised treatment in water-stressed regions, and improving climate resilience. However, existing systems face bottlenecks. Current research (Farrokhpay et al. 2021; Gui et al. 2014) points to persistent limitations in removing ultrafine particles, high energy consumption, vulnerability to load fluctuations and reliance on chemical additives. As wastewater becomes more complex, these weaknesses are magnified. A promising route forward lies in understanding and optimising the underlying hydrodynamics and bubble–particle interactions (Alizadeh Sahraei et al. 2023; Wang et al. 2021; Zhao et al. 2023). The motion of water, air bubbles and particles within a flotation unit governs bubble formation, turbulence, collisions, attachment and separation (Sommer et al. 2024). Only by resolving these micro-processes (Fig. 2) can we unlock step-changes in efficiency, reliability and sustainability.

Research Question and Vision

Key question: How do microscale turbulent structures influence bubble–particle interactions during flotation in wastewater treatment, and how can this knowledge inform sustainable process design?

The project aims to answer this question through three-dimensional, time-resolved measurements of bubbles and particles, bridging fundamental fluid mechanics with chemical flotation applications. The overarching vision is to develop sustainable, energy-efficient flotation systems that recover fine and ultrafine particles more effectively while reducing environmental footprints. By exploring bubble–particle interactions under controlled turbulence, the project will lay the groundwork for the next generation of flotation processes across water treatment, mineral processing and wastewater management.

Focus Topics

- Mechanistic understanding of bubble–particle interactions: Using high-resolution Tomographic Particle Image Velocimetry (Tomo-PIV) to capture the role of microscale turbulence in enhancing or hindering flotation efficiency.

- Data-driven and physics-based flotation modelling: Developing and validating coupled CFD–Population Balance Models (PBM) with experimental data to predict and optimise flotation performance under varying conditions, enabling sustainable process design.

Research Approach

Experimental Platform:

Experiments will be carried out in a state-of-the-art jet-stirred turbulence tank at TU Wien’s Institute of Fluid Mechanics and Heat Transfer (Prof. Alfredo Soldati). This facility is among the few worldwide capable of generating homogeneous isotropic turbulence at high energy dissipation rates (O(1 m²/s³)). Opposing jet arrays with velocities of 2–8 m/s allow fine control of dissipation from O(0.001) to 1 m²/s³. This environment enables systematic study of how turbulence intensity shapes bubble–particle collision, attachment and detachment.

Link to Chemical Flotation:

Results from the turbulence tank will be integrated with experiments in flotation test apparatuses at the Institute of Process Engineering, JKU Linz. Here, disperser designs and bubble size distributions will be optimised and validated. Unique data processing and simulation tools developed in recent years (Mahmoudi et al. 2024; Outokesh et al.; Schäfer et al. 2019; Schick et al. 2024) will be leveraged to characterise bubble and particle behaviour at high temporal and spatial resolution.

Numerical Modelling:

Complementary simulations will use CFD, compartment models and PBM to explore both local flow phenomena and overall process efficiency. Machine learning algorithms will support automated bubble and particle recognition and trajectory tracking, closing the loop between experiment and simulation.

Research Facilities and Resources

- TU Vienna: Jet-stirred turbulence tank; in-house high-speed imaging and Tomo-PIV systems; established simulation codes for turbulence and multiphase flow.

- JKU Linz: Custom-designed pilot flotation facility; analytical instrumentation (UV/VIS, ICP-OES, TOC); digital microscopes and multiple high-speed cameras; proprietary CFD and image-analysis software.

- High Performance Computing: Both institutes provide HPC infrastructure for complex CFD–PBM simulations.

- Data Management: All data will be stored securely and, following FAIR principles, made available via open access or on request.

Expected Outcomes and Impact

- Scientific advances: First-ever detailed maps of bubble–particle interactions under controlled homogeneous turbulence; improved mechanistic understanding of collision, attachment and separation at microscale.

- Modelling breakthroughs: Validated CFD–PBM frameworks linking microscale physics to full-scale flotation performance, enabling predictive design rather than empirical tuning.

- Technological innovation: First guidelines for disperser and bubble-size optimisation; pathways to reduce energy and chemical consumption; improved capture of ultrafine particles.

- Societal benefits: More efficient, robust and sustainable flotation processes that help industries comply with tightening environmental regulations, reduce pollutant discharge, recover resources and support water reuse in stressed regions.

While this project represents one brick in of a highly complex research topic, our vision is to create an internationally visible research cluster dedicated to developing the next generation of sustainable, energy-efficient flotation systems. This cluster will bring together leading research groups at JKU Linz, TU Wien, and partner institutions, integrating advanced experimental platforms with high-performance simulation and data-driven approaches. The current PhD project on bubble–particle interactions under turbulence serves as a keystone pilot, generating unique data and models that the cluster can expand across different scales, materials, and industrial applications.

References

Alizadeh Sahraei, A., Azizi, D., Mokarizadeh, A. H., Boffito, D. C., & Larachi, F. (2023). Emerging trends of computational chemistry and molecular modeling in froth flotation: A review. ACS Engineering Au, 3(3), 128–164.

Farrokhpay, S., Filippov, L., & Fornasiero, D. (2021). Flotation of fine particles: A review. Mineral Processing and Extractive Metallurgy Review, 42(7), 473–483. https://doi.org/10.1080/08827508.2020.1793140

Gui, X., Liu, J., Cao, Y., Cheng, G., Li, S., & Wu, L. (2014). Flotation process design based on energy input and distribution. Fuel Processing Technology, 120, 61–70. https://doi.org/10.1016/j.fuproc.2013.12.011

Mahmoudi, S., Saeedipour, M., & Hlawitschka, M. W. (2024). Bubble dynamics under the influence of the Marangoni force induced by a stratified field of contamination. Experimental and Computational Multiphase Flow, 6(4), 353–364. https://doi.org/10.1007/s42757-023-0182-x

Outokesh, M., Saeedipour, M., & Hlawitschka, M. Understanding bubble-cylinder interactions: Experimental insights into cutting dynamics and liquid film evolution. Advance online publication. https://doi.org/10.2139/ssrn.5191058

Schäfer, J., Hlawitschka, M. W., Attarakih, M. M., & Bart, H.‑J. (2019). Experimental investigation of local bubble properties: Comparison to the sectional quadrature method of moments. AIChE Journal, 65(10), Article e16694. https://doi.org/10.1002/aic.16694

Schick, Y., Weber, G. H., Da Silva, M., Martelli, C., & Hlawitschka, M. W. (2024). Flow monitoring in a bubble column reactor by Distributed Acoustic Sensing. Tm – Technisches Messen, 91(s1), 14–19. https://doi.org/10.1515/teme-2024-0048

Wang, H., Yan, X., Li, D., Zhou, R., Wang, L., Zhang, H., & Liu, Q. (2021). Recent advances in computational fluid dynamics simulation of flotation: a review. Asia-Pacific Journal of Chemical Engineering, 16(5), Article e2704. https://doi.org/10.1002/apj.2704

Le Zhao, Liu, D., Lin, J., Chen, L., Chen, S., & Wang, G. (2023). Estimation of turbulent dissipation rates and its implications for the particle-bubble interactions in flotation. Minerals Engineering, 201, 108230. https://doi.org/10.1016/j.mineng.2023.108230

About the Hosting Institute

The Institute of Chemical Process Engineering at Johannes Kepler University Linz combines classical process-engineering principles with applied experimental and numerical research aimed at resource-efficient, sustainable processing and industrial relevance. Situated on the JKU campus in Linz, the Institute bridges chemistry and engineering: it translates scientific findings into technically viable processes, develops pilot-scale equipment and measurement methods, and trains students for careers in chemical technology and process development. Since October 2020 the Institute is led by Univ.-Prof. Dr.-Ing. habil. Mark W. Hlawitschka.

Research at the Institute is focused on core areas of process engineering where chemical, thermal and mechanical unit operations interact. Key themes include mass transfer and gas–liquid processes (bubble columns and gas absorption), separation technologies (membranes, extraction, absorption, sorption), reaction and reactor engineering, instrumentation and process automation, and computational fluid dynamics for process modelling and scale-up. As an example, key research on black mass recycling from lithium ion batteries was made gaining high attraction from academia and industry. Projects often aim at environmental and sustainability goals – for example, optimizing bubble column systems for CO₂ capture and reuse, improving energy- and resource-efficient separation schemes, and developing measurement and control techniques suited for modern chemical-technology applications.

The Institute pursues an integrated experimental–numerical approach. Laboratories and small pilot facilities (“Technikum”) enable hands-on studies of unit operations, scale-up tests, and validation of modelling approaches; these are complemented by advanced simulation tools and CFD to analyse flows, mass transfer, and multiphase interactions. This combination of bench-scale experiments, pilot testing and computation supports technology development from concept through demonstration and provides students with practical experience relevant for industry and research.

Teaching and education form a central part of the Institute’s mission. The Institute contributes core courses to bachelor and master programmes in Chemistry and Chemical Technology as well as elective and advanced courses in Chemical Process Engineering, Chemical Reaction Engineering, and Instrumentation & Process Automation. It supervises bachelor, master and doctoral theses, offering students a wide selection of thesis topics that connect theory with experimental and numerical practice.

Collaborations with regional industry, national research centres and international projects are an important aspect of the Institute’s profile. Through partnerships, contract research, and participation in interdisciplinary initiatives, the Institute applies process-engineering tools to real-world problems – for example in plastics and polymer processing, carbon capture technologies, waste water treatment and the development of measurement and automation solutions. The existing collaborations facilitate technology transfer, student internships, and applied research opportunities.

The Institute contributes to journals and conferences (such as Distillation and absorption, 2026 in Salzburg), publishes review and perspective pieces on process-engineering topics, and participates in events that connect academia with industry and policymakers. For prospective students and collaborators the Institute offers a clear gateway to applied process engineering: structured coursework, supervised thesis projects (Bachelor, Master, PhD), experimental training in the Technikum, and access to numerical modelling expertise. The Institute’s work is well suited to those interested in multiphase flows, separation and conversion processes, instrumentation and automation, as well as applied sustainability solutions in chemical engineering.

About the Principal Investigator / PhD Supervisor

Univ.-Prof. Dr.-Ing. habil. Mark W. Hlawitschka

Personal / Position

- Head (Leiter) of the Institute of Process Engineering (“Institut für Verfahrenstechnik”) at Johannes Kepler Universität Linz.

- Since 1 October 2020 holding the professorship / leading the institute.

Scientific Qualifications

- 2019: Venia docendi (habilitation) in Thermal Process Engineering, TU Kaiserslautern

- Topics: reactive bubble columns, multiphase hydrodynamics

Education & Habilitation

- 2003–2008: Dipl.-Ing. Mechanical & Process Engineering, TU Kaiserslautern, Germany

- 2002–2003: Distance learning, Electrical Engineering, TU Kaiserslautern

- 2013: Dr.-Ing. (PhD) “with distinction” at TU Kaiserslautern, Supervisor Prof. Hans-Jörg Bart

Positions & Career

- Since 10/2020: Univ.-Prof., Head of Institute of Process Engineering, JKU Linz

- 2020: Call to University of Innsbruck (list position 1)

- 2013–2020: Post-doc / Project Manager (Habilitand), TU Kaiserslautern

- 2013–2016: Lecturer at DHBW Mannheim

- 2009–2013: Research Assistant, TU Kaiserslautern

- 2007–2008: Internship at BASF Sonatrach, Spain

- 2003: Internship at BASF Ludwigshafen, Germany

Academic & Research Career

- Prior to his full professorship at JKU, he was active in research leadership roles, including project lead of several AiF-projects, DFG projects in SPP 1740 (a DFG research program).

- He was speaker of the TU Nachwuchring (young researchers’ group) since about 2017.

- Received calls (“Rufe”) from University of Innsbruck and from JKU, selecting JKU.

Research Interests / Expertise

- Multiphase systems: especially bubble columns, reactive bubble columns, liquid-liquid extraction, mass transfer, hydrodynamics and interactions between flow, droplet dynamics, coalescence, fouling.

- Computational Fluid Dynamics (CFD), population balance modelling, measurement methods (droplet size, velocity etc.), scale-up from laboratory / pilot scale.

- Resource-efficient / sustainable processing: topics include extraction of rare earths, wastewater purification, CO₂ capture & usage, and the digitization / online monitoring & control of process units.

Selected Research Projects (2022–2027)

- Africa Uni-Net (2025–2027): Closing the loop on battery waste for environmental restoration

- OeAD India (2025–2027): Advanced computational and machine learning for biofouling control in membrane distillation

- Industry Project (2024–2026): Flotation

- FWF PARBUIN (2023–2026): Particle–bubble interactions for green processes (bubble dynamics in slurries)

- FFG/Comet & industry projects (2022–2024): Methanization in bubble columns, membrane distillation studies

- Since 2021: Austrian delegate, EFCE Working Party Fluid Separations

Honors / Awards / Recognition

- “Forschungspreis des Jahres 2022” from GVT (Forschungsgesellschaft Verfahrenstechnik) for project DisKoPump, which he led (in collaboration with RWTH Aachen & TU Kaiserslautern).

- In 2023, project under his leadership (“Entwicklung von hochgefüllten dünnwandigen Kunststoffelementen …“) was awarded “Projekt des Jahres 2023” by GVT.

- Recognized as “Top Reviewer” in 2021 in journal Chemical Engineering Research and Design.

Selected Publications

- Outokesh, Masoud; Saeedipour, Mahdi; Hlawitschka, Mark W. (2025). Understanding bubble–cylinder interactions: Experimental insights into cutting dynamics and liquid film evolution. Chemical Engineering Journal, 519, 164796. DOI: 10.1016/j.cej.2025.164796

- Mahmoudi, Sadra; Hlawitschka, Mark W. (2021). Effect of Solid Particles on the Slurry Bubble Columns Behavior – A Review. ChemBioEng Reviews, 9(1), 63-92. DOI: 10.1002/cben.202100032

- Mühlbauer, Adam; Hlawitschka, Mark W.; Bart, Hans-Jörg. (2021). Modeling of solid-particle effects on bubble breakage and coalescence in slurry bubble columns. Experimental and Computational Multiphase Flow, 3(4), 303-317. DOI: 10.1007/s42757-020-0078-y

- Nedeltchev, Stoyan; Mörs, Friedemann; Mühlbauer, Adam; Hlawitschka, Mark W.; Graf, Frank; Kolb, Thomas; Bart, Hans-Jörg. (2021). Reliable identification of the first transition velocity in various bubble columns based on accurate sophisticated methods. Chemical Engineering Research and Design, 165, 409-425. DOI: 10.1016/j.cherd.2020.11.013

- Schäfer, J.; Schmitt, P.; Hlawitschka, Mark W.; Bart, Hans-Jörg. (2019). Measuring Particle Size Distributions in Multiphase Flows Using a Convolutional Neural Network. Chemie Ingenieur Technik, 91, 1688-1695. DOI: 10.1002/cite.201900099

- Mühlbauer, Adam; Hlawitschka, Mark W.; Bart, Hans-Jörg. (2019). Models for the Numerical Simulation of Bubble Columns: A Review. Chemie Ingenieur Technik, 91, DOI: 10.1002/cite.201900109